|

| Drying / Curing |

| Tobacco Curers |

|

|

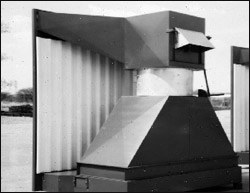

In the late 60's the company produced Transportable units for curing tobacco. This was a great improvement on the old store buildings that were built and heated by fires inside to dry the leaves. The curers kept improving over the years as new technology became available. The latest models are heated by coalfired heat exchangers and the leaves are pack nice and tight into frames. These frames slide onto rails inside the curer and are evenly spaced for the best curing results. Water-to-air heated units are also available, and provide a much cleaner enviroment as there are less coalfires to maintain. The hot water is provided via a coalfired hot water kettle, and is pumped through radiators that heat up the air in the kilns. The Tobacco curers can use either a coal fired air-to-air heat exchanger of 150kW, or a Radiator heated by one of our Kettles to produce heat for curing tobacco leaves. The leaves are packed into frames, that slides onto rails inside the curing compartment, for easy loading and unloading. The temperature is automatically controlled with electronic thermostats, and humidity control is also available. These curers are manufactured and assembled inside the factory, and is transportable in the completed form. When delivered, the unit is lowered from the truck into position, and after connecting the main power it is ready for use. The structure is painted with a specially developed heat resistant durable paint, and covered on both sides with galvanized sheets. An evenly spaced set of floorplates that is also made from galvanized material, ensures even airflow throughout the curing compartment for a high quality end product. |

|

|

Replacement Units |

| Tabak Droërs |

Gedurende die laat 60's het die maatskappy begin om vervoerbare oonde te vervaardig vir die droging van tabak. Dit was `n groot verbetering op die ou tabakskure wat gebou was en verhit is met vuuroonde binne om tabakblare te droog. Die oonde is aanhoudend verbeter soos nuwe tegnologie dit moontlik gemaak het. Die nuutste modelle word verhit met lug-tot-lug hitteruilers wat met `n outomaties ondervoerstoker en steenkool brander aangedryf word. Tabakblare word in beskermende rame styf gepak en dan in oond gedroog. Water-tot-lug eenhede is ook beskikbaar en sorg vir `n 'skoner' omgewing, aangesien daar slegs een vuur area is vir tot soveel as 10 oonde. Die warm water word voorsien vanaf een van ons warm water ketels, en word deur water klosse 'radiators' gesirkuleer om sodoende die lug te verhit. Die Tabak oonde kan verhit word met een van twee tipes verhitting. Daar kan gebruik gemaak word van `n 150kW lug-tot-lug hitteruiler, of `n waterklos wat deur een van ons Ketels kan verhit word, om hitte te verskaf vir die droging van tabak. Die tabak blare word in rame gepak wat op glyspore in die drogins kompartement ingestoot word vir vinniger in - en uitlaai. Die temperatuur in die oonde word outomaties beheer met elektroniese termostate, en vogbeheer is ook beskikbaar op aanvraag. Die droërs word kompleet vervaardig by die fabriek, en dan volledig vervoer. Op terrein word die droër van die trok afgelaai en in posisie geskuif. Na koppeling van die elektriese toevoer kabel is dit onmiddelik gereed vir gebruik. Tydens vervaardiging word die struktuur geverf met spesiale hitte bestande verf en dan oorgetrek met gegalviniseerde materiaal. `n Stel eweredig gespasieerde vloerplate sorg vir gebalanseerde wind verspreiding in die oond, om `n beter eindproduk te verseker. Verskeie onderdele is beskikbaar vir die oonde. |

Vervangings eenhede / omskakelings |

| Timber |

|

|

Two types of kilns have been developed for the curing of timber: 1.) Progressive Kilns 2.) Compartment (Batch) Kilns Stacking of trolleys High Quality Heat source |

| Hout Droogoonde |

|

|

Twee tipes oonde is ontwikkel vir die droging van hout: 1.) Progressiewe Oonde 2.) Kompartement Oonde Opstapel van hout op trollies Hoë Kwaliteit Hitte Bron |

| Grain / Rice / Bean Drying |

|

|

Various sizes machines have been developed for this type of drying, and it is possible to dry from 3 tons up to 6 tons of wet product per hour. Larger capacities could be dried per hour, depending on the percentage of moisture. How it works: Maintenance: |

| Graan / Rys / Bone Droging |

Verskeie groottes eenhede is ontwikkel vir die doel, en droging van 3 ton tot 6 ton per uur is moontlik. Groter hoeveelhede kan gedroog word, afhangende van die persentasie vog wat afgedryf moet word. Hoe dit werk: Onderhoud: Al die eenhede word kompleet vervaardig en in seksies afgelewer. Na montering en koppeling van elektriese toevoer is dit onmiddelik gereed vir gebruik. |