DOWNLOADS

Brochure/Flyer

Data Spreadsheet

|

R-102™ Restaurant Fire Suppression Systems

The ANSUL® R-102™ Liquid Agent System continues to be the #1 protector of today’s kitchen equipment. Choose from either of two design options…

Appliance-Specific Design. The most efficient fire protection is accomplished when nozzles are selected and aimed at specific hazard areas on each appliance. This method typically provides the most economical use of liquid agent reducing the size or quantity of storage tanks and associated hardware.

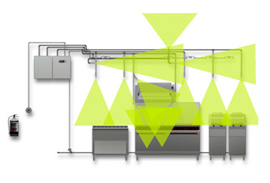

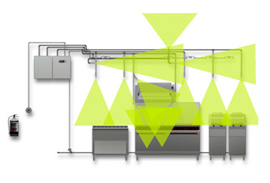

Overlapping Appliance Protection. When flexibility and simplicity are most important, nozzles are placed in a straight-line arrangement providing overlapping agent discharge patterns. This creates a virtual fire-free zone where appliances of various types and sizes are protected - even if they are replaced or rearranged under the hood. R-102™ Overlapping Appliance Protection

THIS IS BIG! ANSUL® R-102™ Overlapping Applicance Protection has EXPANDED. Greater spacing between nozzles and simplified piping guidelines are just two of the many enhancements now offered. When flexibility and simplicity are the most important features for a kitchen design, ANSUL Overlapping Appliance Protection provides a virtual zone of protection where appliances of various types and sizes are protected – even if they are replaced or rearranged under the hood.

- Nozzle Spacing – Expanded from 12 in. (305 mm) to 25.5 in. (647 mm).

- New Simplified Piping Rules

- Range Protection

- Hardware Reduced

- Appliances may be interchanged freely or upgraded

- Existing Appliance Specific Nozzles

- Detection Placement

- Standard R-102 Components

- Overlapping system design is flexible and simple.

Nozzles are installed in a straight line with a maximum nozzle spacing of 25.5 in. (647 mm) and a height of 40-45 in. (1016-1143 mm) above the cooking surface. In this design nozzles are not aimed individually at specific appliances but instead are consistently aimed at the hazard zone centerlines. These overlapping discharge patterns create a continuous zone of protection in which all appliances within this area are protected.

Frequently Asked Questions (FAQs)

- How are tilt skillets and tilt braising pans protected?

Currently, there is no UL test for tilt skillets and braising pans. However, UL has stated that because these appliances can be used for frying, they must be protected as fryers. Multiple nozzle protection for fryers is limited by UL to fry vats not exceeding 6 sq. ft. (864 sq. in.). This limitation does not apply when multiple nozzle protection is used for tilt skillets and braising pans. Also, because tilt skillets/braising pans do not have insulated sides to the cooking pan, the maximum dimensions (area and longest side) for fryers with drip boards, can be used.

- At what point does an existing dry chemical or wet chemical system need to be upgraded to a UL 300 wet chemical system?

UL 300 changes affect only pre-engineered restaurant fire suppression systems manufactured after November 20, 1994. All existing R-102 installed systems are "grandfathered" and remain listed using the UL guidelines in effect at the time of manufacture (R-101 Dry Chemical System service and replacement components are no longer available. Consequently, this system is no longer listed, according to Underwriter’s Laboratories (UL)). To ensure the best fire protection available in applications where vegetable oil is used in depths greater than 1/4", a UL 300, R-102, or PIRANHA wet chemical fire suppression system should be used.

- Can carbon dioxide cartridges be used instead of nitrogen in pre-UL 300, R-102™ systems?

No. Even though the system may operate satisfactorily, pre-UL 300 R-102 systems still require the use of nitrogen cartridges to comply with their listings.

- Can the Hose/Grommet Pkg. (Part No. 418511) be used to connect to an add-on tank with painted bracket? Also, do you have to manifold two tanks together to use the Hose/Grommet Pkg?

The Hose/Grommet Pkg. can be used with the add-on tank in the stainless steel enclosure, or an add-on tank in a painted bracket (if acceptable to the Authority Having Jurisdiction). The Hose/Grommet Pkg. can be utilized either with manifolded agent discharge piping or when two tanks are piped separately.

- How are industrial fryers (potato chip, corn chip, pork rind, etc.) or large donut fryers protected?

UL will not allow multiple nozzle protection for fryers that exceed 6 sq. ft. (864 sq. in.)* unless the fire suppression system manufacturer obtains a listing for the protection of the specific appliance brand and model number of the fryer (i.e., Krispy Kreme Fryers – Models 150 D/H, 270 D/H, 600 D/H, and 1000 D/H). As an alternative, an engineered carbon dioxide system may be used when designed in accordance with NFPA 12. Under certain conditions, a PIRANHA wet chemical system may be used. Contact Ansul Technical Services for assistance.)

- How are ranges protected when a shelf or salamander broiler is installed above the back of the range?

UL has designed a test for ranges that have shelves installed. Shelves and salamander broilers can obstruct the discharge pattern of a nozzle when it is installed over the center of the range. Therefore, a low proximity nozzle(s) must be used under a salamander or shelf. Or, a specifically listed nozzle designed to protect a range when a shelf is present must be used.

|